01

How to create stable, safe, high-quality bathroom products?

2024-06-04

Creating stable, safe, and high-quality bathroom products requires a comprehensive approach that encompasses various aspects such as production standardization, reasonable design, trial assembly inspection, component testing, and adherence to safety guidelines. These elements are crucial in ensuring that the final products meet the highest quality and safety standards.

One of the key factors in creating stable and safe bathroom products is the implementation of production standardization. This involves establishing a set of standardized processes and procedures for the manufacturing of shower room components. By adhering to strict production standards, manufacturers can ensure consistency in the quality of their products, thereby minimizing the risk of defects and malfunctions.

Furthermore, a reasonable design is essential in creating stable and safe bathroom products. This involves careful consideration of factors such as structural stability, material durability, and user safety. A well-thought-out design not only enhances the overall quality of the product but also minimizes the likelihood of accidents or failures.

Trial assembly inspection is another critical step in the production of high-quality bathroom products. This involves assembling and testing the components of the shower room to identify any potential issues or defects before the final product is manufactured. By conducting thorough inspections during the trial assembly phase, manufacturers can address any issues early on, thereby ensuring that the end product meets the highest quality and safety standards.

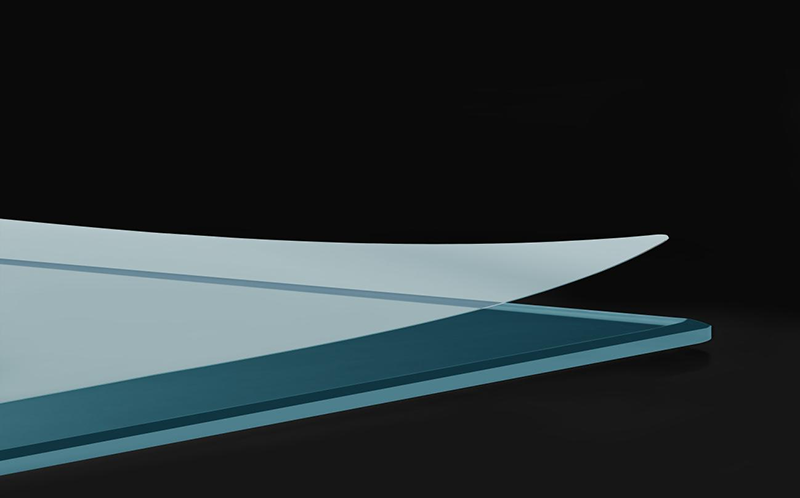

In addition to trial assembly inspection, component testing is also essential in creating stable and safe bathroom products. This involves subjecting individual components of the shower room, such as glass panels, door hinges, and seals, to rigorous testing to assess their performance and durability. By testing each component thoroughly, manufacturers can identify any weaknesses or vulnerabilities and make necessary improvements to enhance the overall quality and safety of the product.

Adhering to safety guidelines and regulations is paramount in the production of bathroom products. Manufacturers must ensure that their products meet all relevant safety standards and regulations to guarantee the safety of consumers. This includes using materials that are certified for their safety and durability, as well as incorporating safety features such as anti-slip surfces and secure door mechanisms.

Ultimately, the creation of stable, safe, and high-quality bathroom products requires a holistic approach that encompasses production standardization, reasonable design, trial assembly inspection, component testing, and adherence to safety guidelines. By prioritizing these key elements, manufacturers can ensure that their shower room products meet the highest quality and safety standards, providing consumers with reliable and durable solutions for their bathroom needs.